WDear Backers,

First of all, thank you sincerely for your patience and trust.We know many of you have been waiting for concrete progress updates, and we truly appreciate your understanding as we carefully move this project forward.

In this update, we want to clearly share:

·what has already been completed,

·what is currently in progress,

·and what potential risks may affect the timeline.

We believe honest and detailed communication is the best way to respect your support.

💰 Funds Received & PledgeBox Reminder

At the end of November, we successfully received the funds from Kickstarter and immediately sent out the PledgeBox survey to all backers.

At the moment, around 30% of backers have not yet completed their PledgeBox survey.

If you are one of them, we kindly ask you to complete it as soon as possible, as this information is critical for us to accurately prepare production and shipping.

👉 Please refer to Update #4 for detailed instructions.

🏭 Production Progress (What We Have Done So Far)

When the funds were received, we immediately started production preparation. Here is our current progress:

1️⃣ Factory Audit & Selection

In early December, our team personally visited multiple factories in Shenzhen, China. After on-site inspections and technical discussions, we selected some factory that meets our requirements for quality control, precision, and production capability. We are currently in the process of finalizing and signing production contracts.

2️⃣ Battery Upgrade (Design Improvement)

During design optimization, we decided to upgrade the battery solution:

• From: Manganese-based lithium polymer battery

• To: Ternary lithium polymer battery

We made this decision after careful evaluation.

We customized a ternary lithium polymer battery specifically for L7, instead of using an off-the-shelf manganese-based battery.

Manganese-based lithium batteries tend to experience noticeable capacity degradation after around 30 charge cycles, which is not ideal for a precision measurement tool.

Ternary lithium batteries provide better cycle life, improved stability, and longer usable lifespan, ensuring a better long-term experience for you. Although this will increase costs.

3️⃣ Custom Laser Module Adjustment

Our custom laser module has been completed, and initial testing has been conducted.

During validation, we discovered that one resistor value needs fine adjustment to achieve optimal performance. We are now modifying the design and proceeding with another round of sampling and testing to ensure accuracy and consistency.

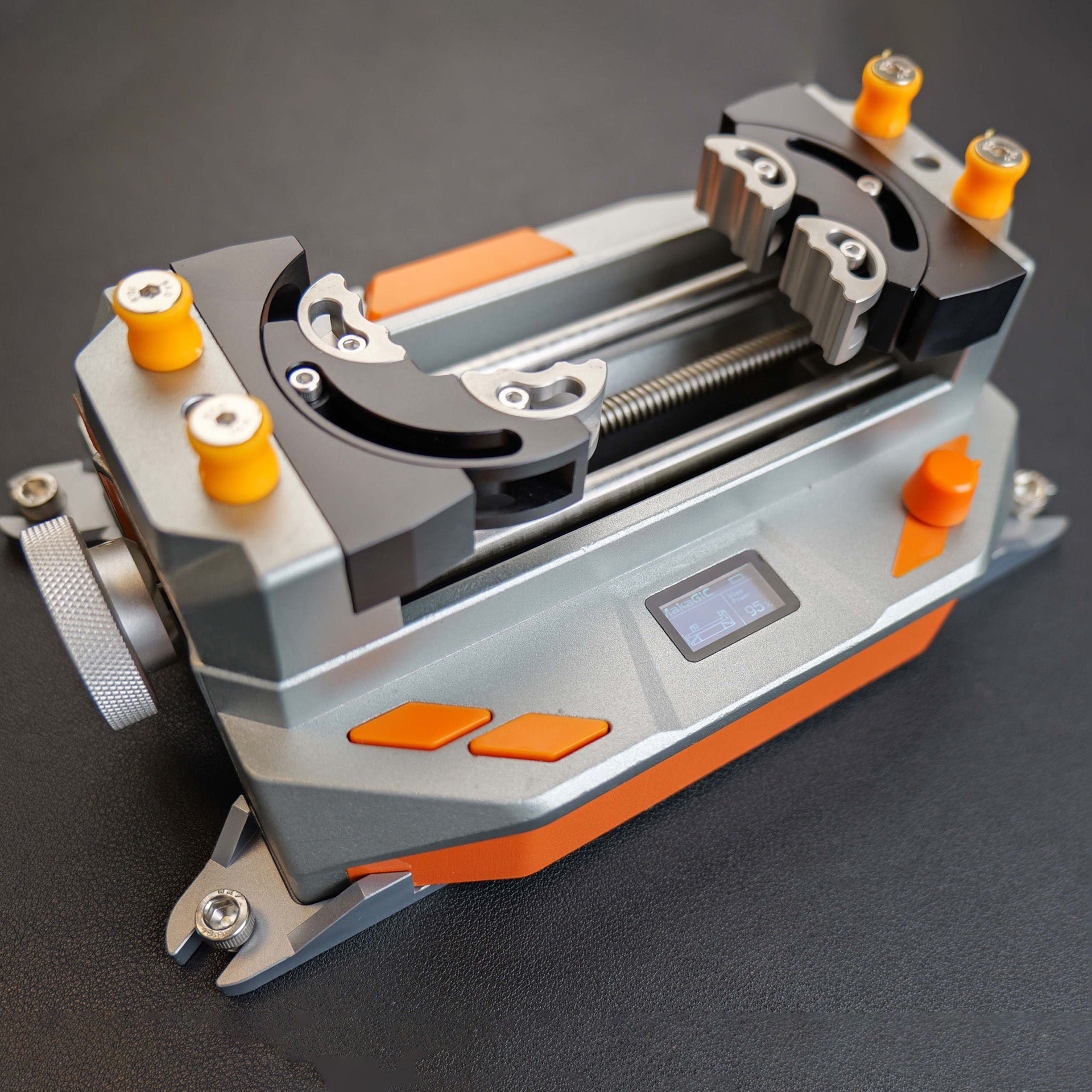

4️⃣ Structural Parts & Mold Preparation

Structural part prototyping and mold design are currently underway.

We expect to start mold design before December 25.

⚠️ Potential Schedule Risks (Shared in Advance)

Overall, the project is progressing in an organized manner.

However, we want to proactively share two factors that may affect the schedule.

1️⃣ TDK Chip Price Increase

One of the key components in our product uses a chip manufactured by TDK (Japan).

In November, the price of this chip increased significantly, which created major cost pressure and temporarily prevented us from completing material procurement as planned.

To address this, we are pursuing two parallel solutions:

Option A: Wait for Price Normalization

Based on our assessment, this price increase appears to be temporary, and we expect pricing to return to an acceptable range by early February.

If so, we will immediately proceed with procurement and production, aiming for late February delivery, although some risk remains.

Option B: Chip Replacement (TDK → TI)

At the same time, our engineering team is redesigning the circuit and firmware to switch to a Texas Instruments (TI) chip.

This involves PCB redesign, new samples, and additional firmware validation. As a result, PCB and software testing may take slightly longer, but we are still planning all work around a late February delivery target.

2️⃣ Chinese New Year Production Window

Our factory is located in Shenzhen, China, and February 2026 coincides with Chinese New Year, the most important holiday in China.

From January to early February:

• Factory schedules become heavily loaded

• Some logistics partners begin holiday shutdowns

This means all production must be completed before the holiday.

We are doing everything we can to push schedules forward, but we want to be honest that this is a challenging period and may introduce shipping delays.

🤝 Our Commitment to You

• We will never compromise product quality

• We will share key milestones as soon as they are reached

• If anything changes, we will communicate early and transparently

🙏 Thank You

Thank you again for your patience and understanding.

If you have any questions, please feel free to leave a comment or contact us directly.

📅 Next UPDATE: Early January

By then, we expect to have completed mold manufacturing and started small-batch pilot production.

With sincere gratitude,

The MakaGiC Team