Dear backers,

First, I would like to express our sincere gratitude for your support.

Since the project launched, our team has mainly been focused on two things: Responding carefully to every question from our backers, to make sure everyone clearly understands the product features, shipping process, and our current progress and promoting the project so that more people can discover this product!

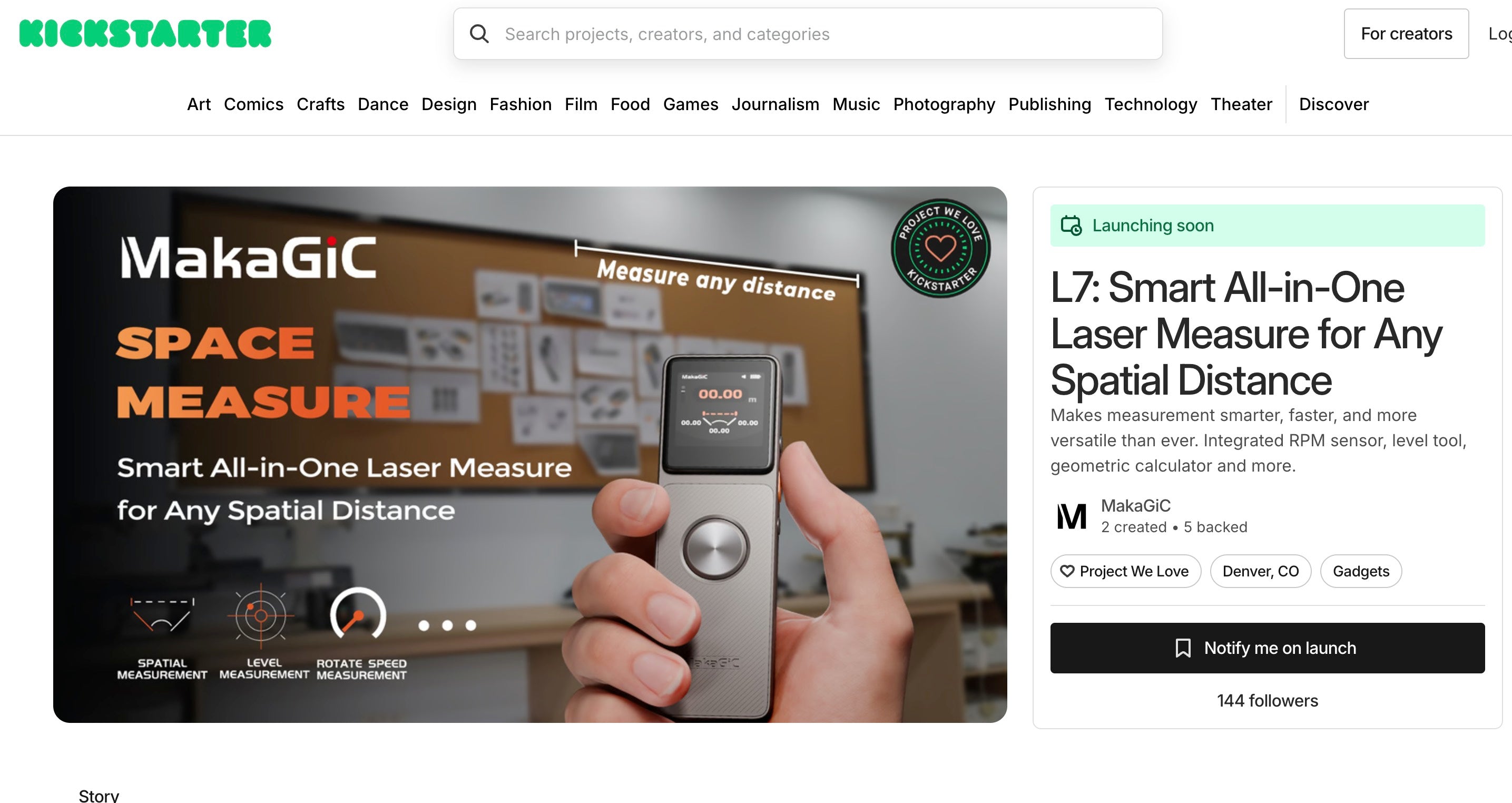

Because we devoted most of our time to these efforts, we are only now publishing our first official update. In this update, we want to share how the L7 came into being. What you will read is not a marketing story, but a real experience that happened during our daily work.

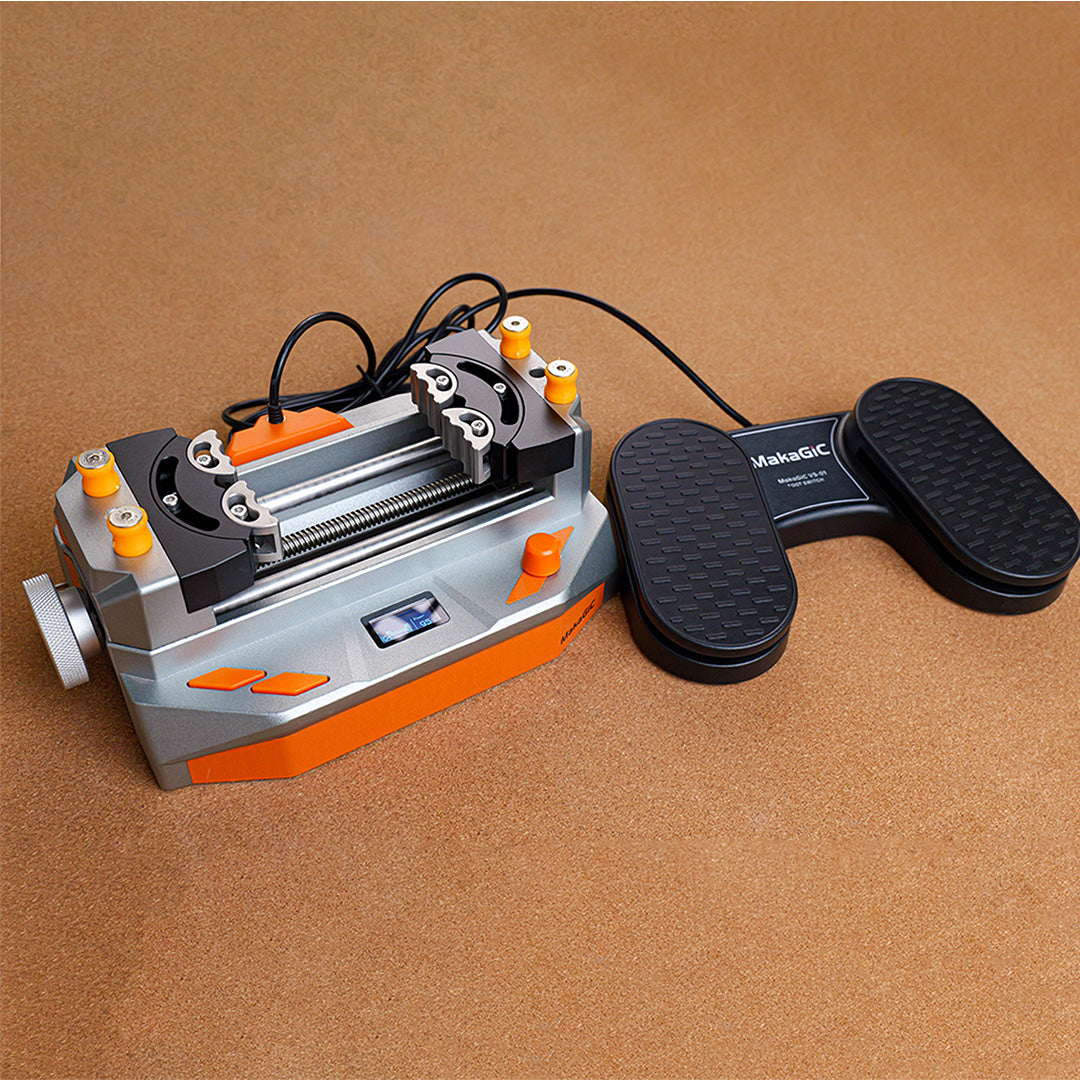

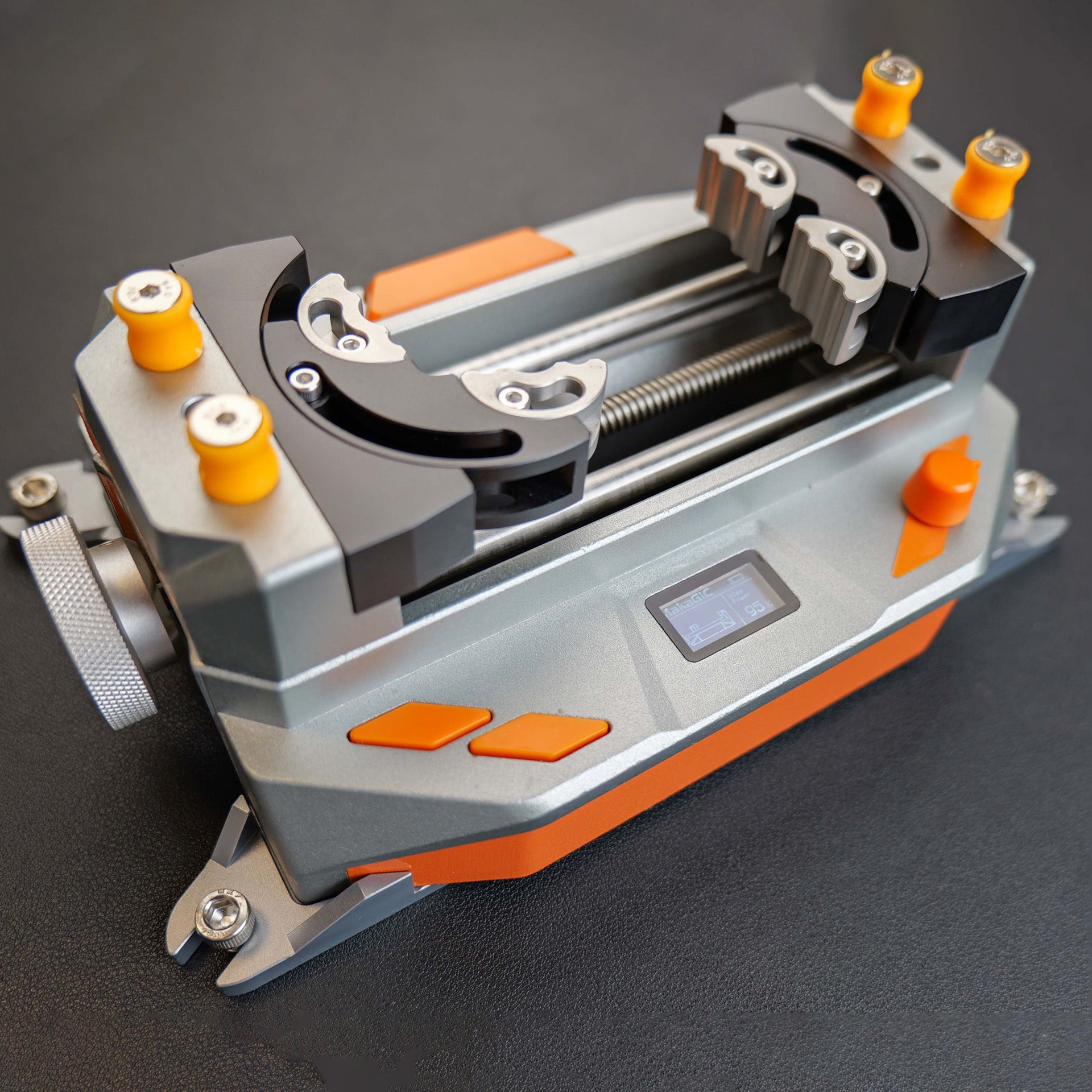

Last year, we were preparing our previous product, MakaGiC VS01, for shipment. According to logistics requirements, we needed to provide the volume of each package to calculate shipping costs. We thought using a traditional laser measuring device would make this process easy, but when we actually started using it, we realized it wasn’t solving the problem. A traditional laser measure must be placed directly against the object to take a measurement. Each side of the box had to be measured one by one, carefully aligned. If the boxes were stacked high or placed farther away, we still had to walk over or move them. In real-world conditions, this process was inefficient and added unnecessary complexity.

This led us to a simple but important question: Could we measure the distance between two points from a distance, simply by moving the device, without having to touch the object itself? This idea was not born out of a desire to build something “cool,” but from a very practical problem we personally encountered and wanted to solve.

Based on this thought, we began exploring a solution that combines a laser with an IMU (Inertial Measurement Unit). The laser provides the distance to a starting point, while the IMU records the movement, angle, and orientation of the device as the user moves it. The algorithm then calculates the actual distance between two points in space. There was no existing solution for this approach, so we had to design the hardware and develop the algorithms entirely from scratch. In our early prototypes, the measurement error was very large and inconsistent, even when performing the same motion repeatedly. To address this, we spent a great deal of time collecting data, analyzing sources of error, building mathematical models, and developing filtering methods to reduce IMU drift.

We also faced the challenge of variations in user movement. In reality, every person holds and moves a device differently, with varying speed and motion. If the algorithm cannot adapt to these variations, the product cannot succeed in practical use. For this reason, we restructured the algorithm many times, enabling it to recognize and adapt to different movements and automatically correct deviation. At the same time, we realized that the way the device is held could affect the measurement, so we repeatedly refined the housing and internal structure to ensure stable performance under natural hand movements.

During development, we didn’t remain in a controlled lab environment. Instead, we tested the prototypes across a variety of real-world scenarios. We measured the distance between walls in underground parking lots, the gap between storage racks in warehouses, height differences in stairwells, and tested stability on uneven surfaces. In one warehouse test, we measured the aisle width between two rows of shelves. Instead of walking over and placing the device against the surface, we simply moved the prototype along the line of sight from a distance, and got the result within seconds. The warehouse manager said, “If this really works like that, it would change how we work every day.” In a home renovation scenario, a team member used the prototype to measure the height to the ceiling from the bottom of a staircase. Previously, this required climbing or extending the device against the wall, but using the L7 prototype, it was completed from a distance with a simple hand movement. These real-world tests helped us continuously refine the algorithm and also confirmed that this approach had real practical value.

As we continued developing the measurement system, we also considered additional needs in real work scenarios. This led us to integrate features such as a level tool, angle measurement, and tachometer (RPM measurement). These features were not added for marketing purposes, but because they are genuinely useful in DIY, installation, construction, and equipment setup environments. Our goal is for the L7 to be not just a measurement device, but a tool that users will actually keep in their daily toolkit.

Many people have asked why we didn’t use standard off-the-shelf components to reduce cost. I want to be very open here: all the core components of the L7—including the laser module, IMU data processing architecture, main control system, and algorithms—were developed by our own team. There are no existing commercial modules that meet these requirements, which is why we built them ourselves. As a result, the development cost and hardware cost are much higher than that of conventional laser measuring tools.

Even so, we decided to offer the L7 at a user-friendly price. In the early stage, our profit margin is very limited, and in some cases, it is almost at cost. We made this decision because we want more people to be able to use this product and help bring this new measuring method into real-world applications. We believe that once more users adopt the product and the order volume increases, we will be able to negotiate lower manufacturing costs from suppliers, and only then will we achieve a healthy profit margin. So please rest assured: our pricing is not due to cutting corners, but a strategic decision to make this technology accessible and sustainable in the long term.

We are deeply grateful for every backer who supports us. Your trust is the reason this product can exist, and your support gives us the motivation to continue pushing forward in the development of new tools.

— The MakaGiC Team