We're thrilled to share the latest updates on the progress of our project as we transition into the production phase. Your continued support and patience mean the world to us.

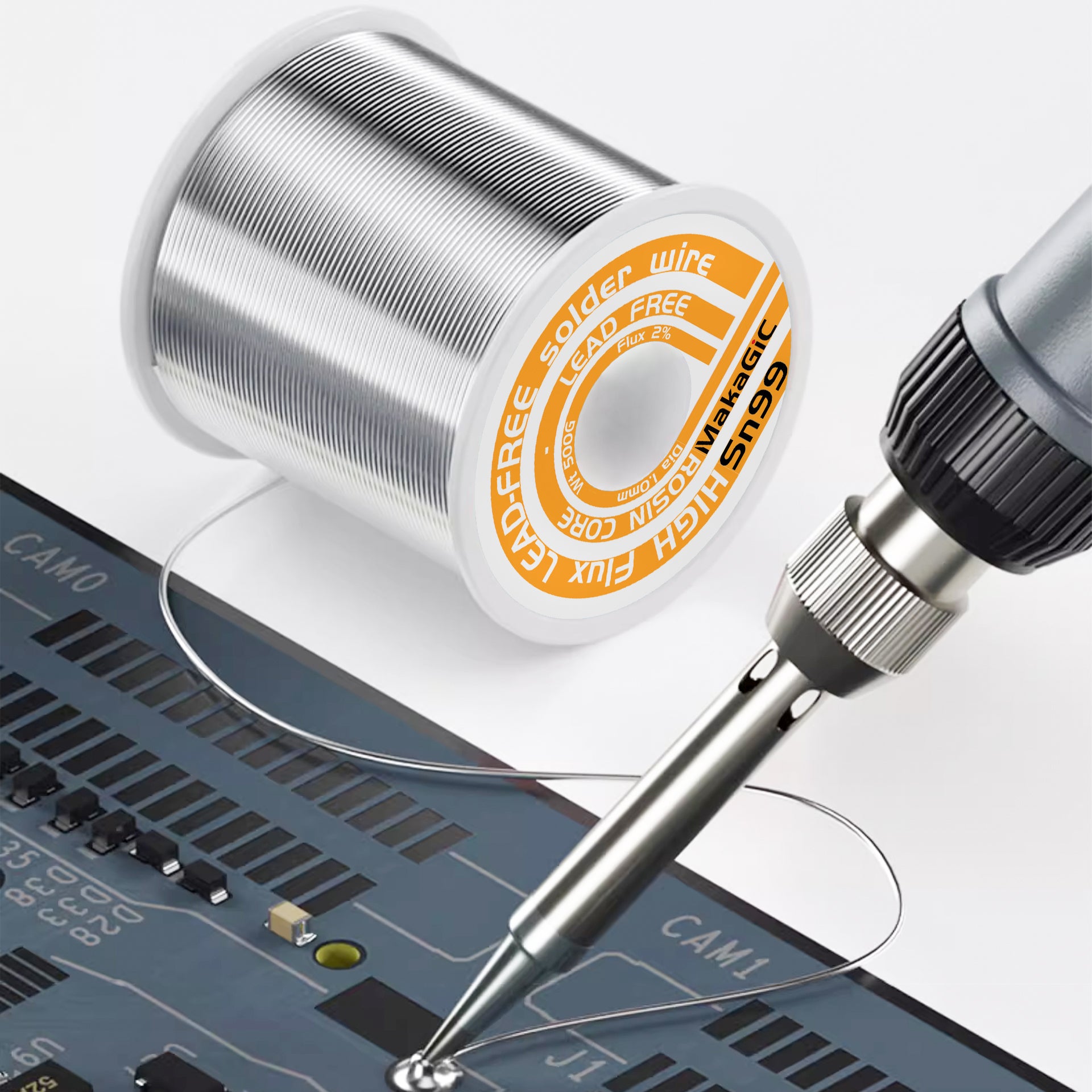

Since the successful crowdfunding campaign, our team has continuously inspected and reviewed suppliers. This month, we've signed contracts with over eighty percent of our parts suppliers, preparing for the imminent production of Makagic.

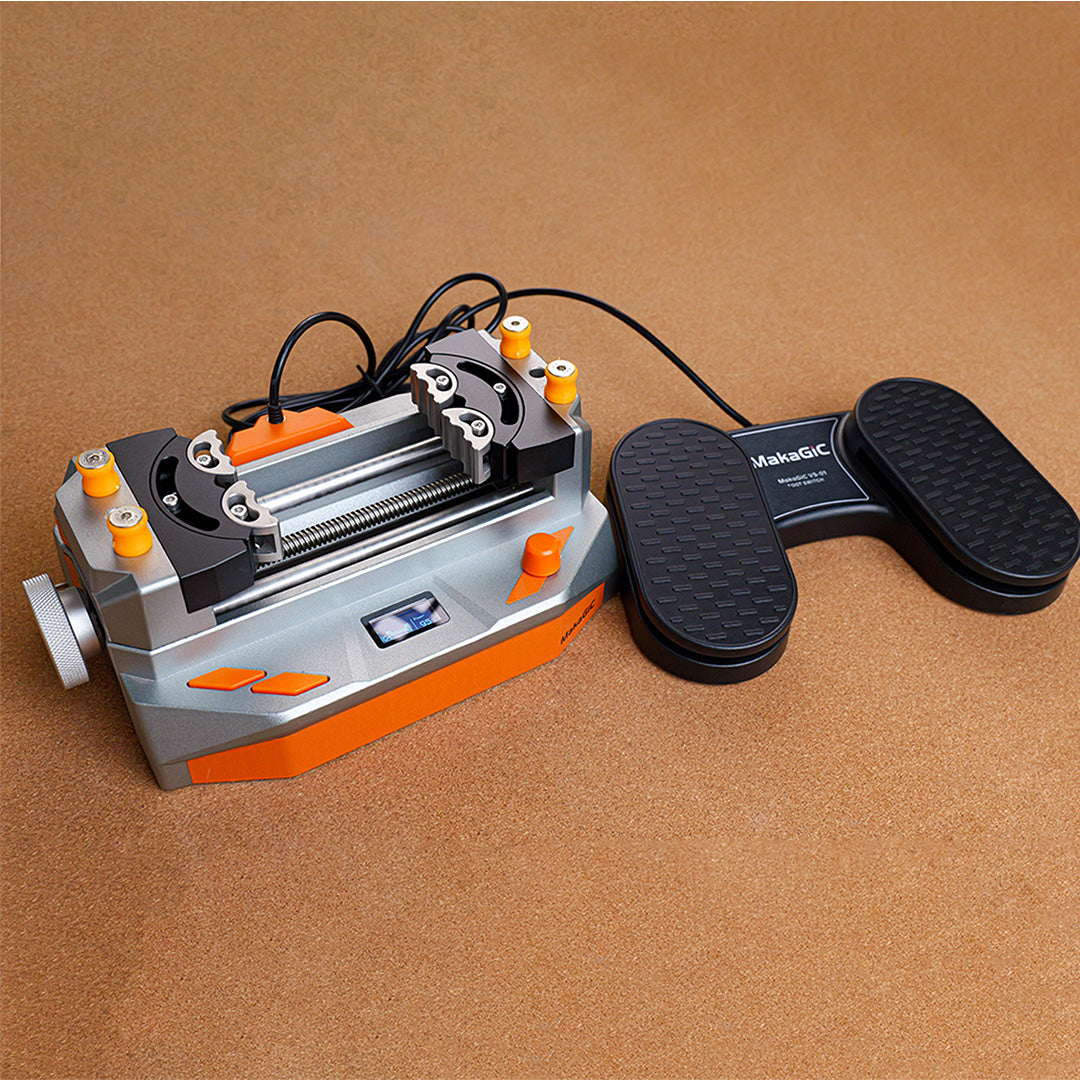

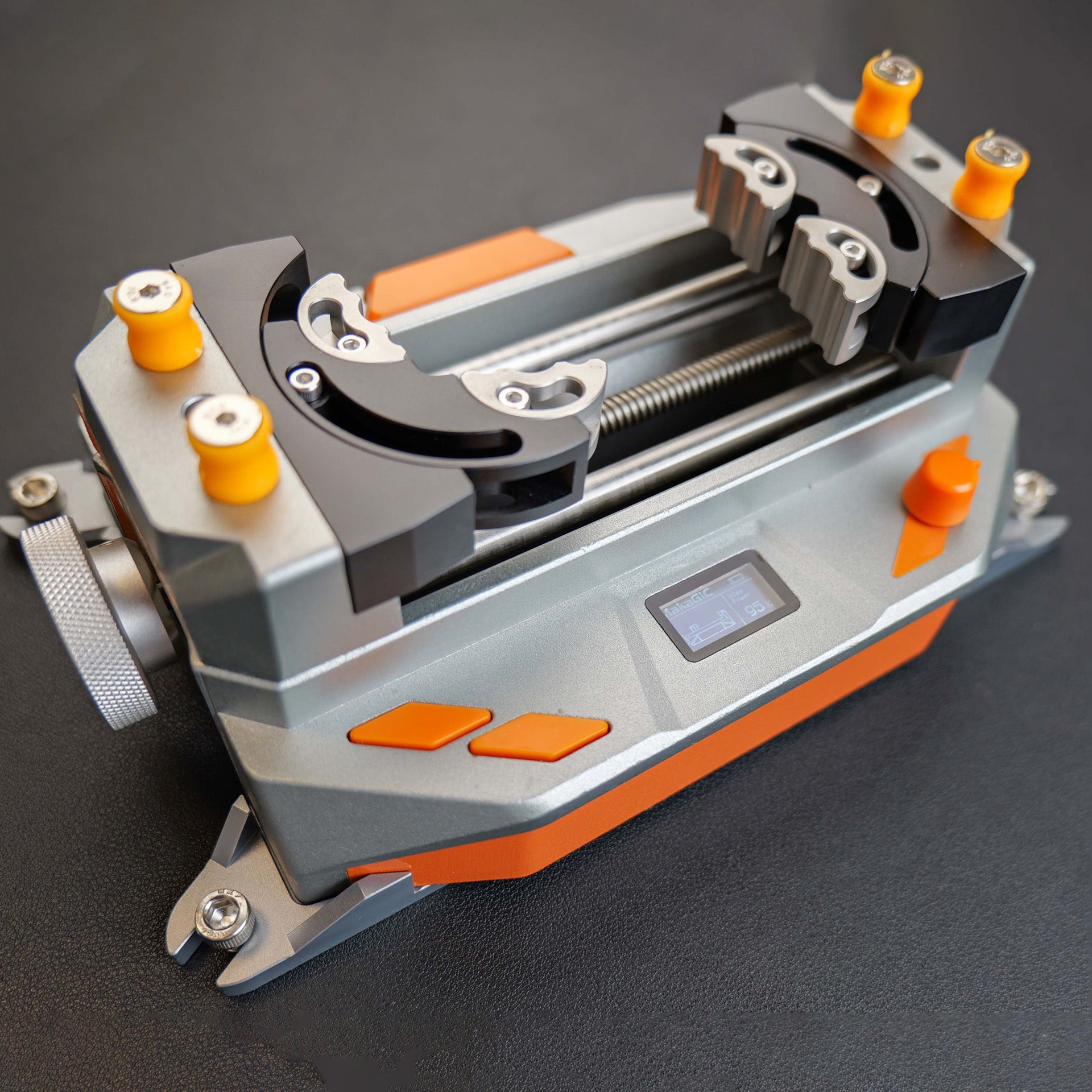

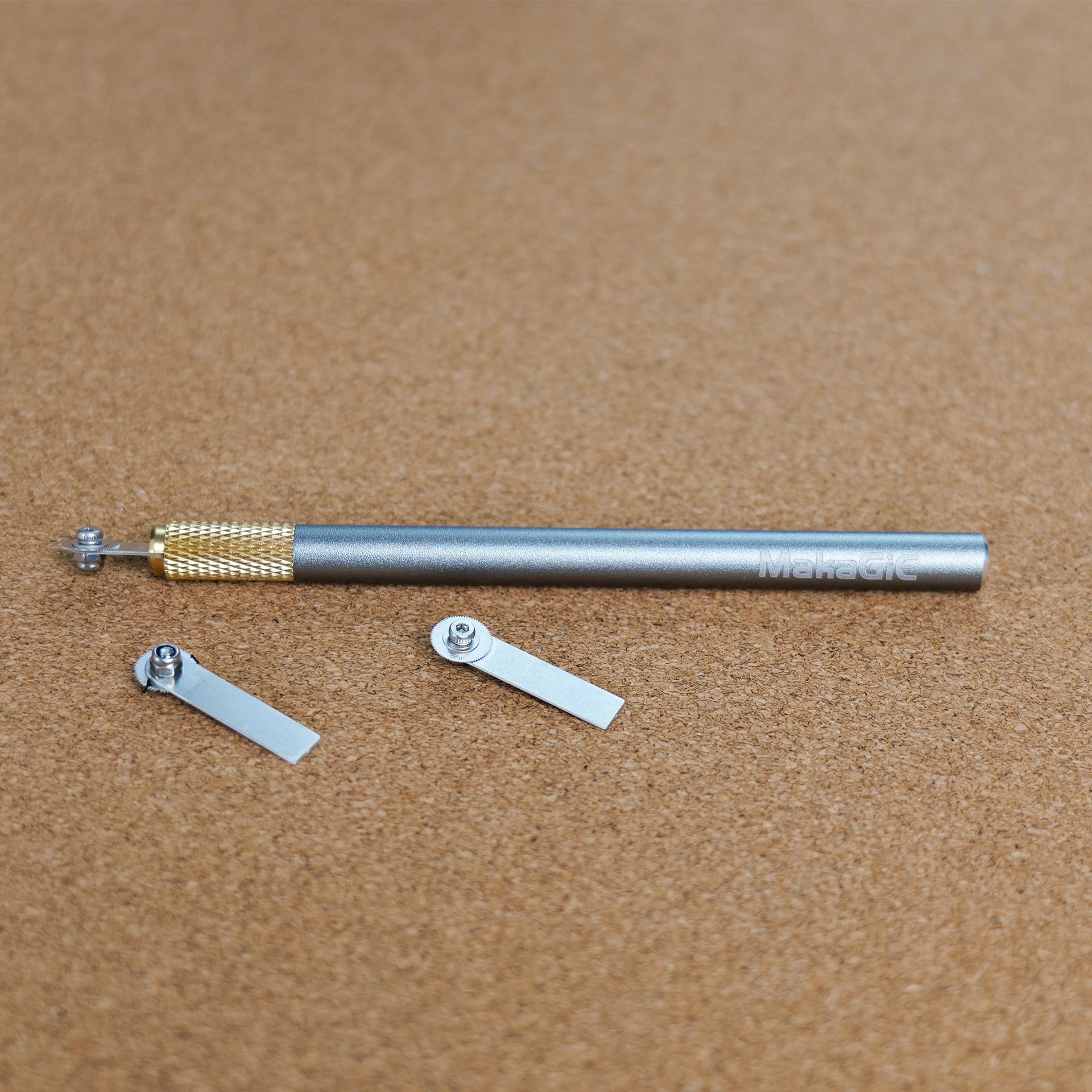

Simultaneously, our mold supplier for MakaGiC VS01 has been diligently working on the molds. Below is a diagram of the main body mold for VS01. Molten aluminum flows through the central channel under pressure into the mold. Once cooled, we obtain the main part of Makagic vs01.

The blue sections in the image represent the channels.

The complete die-casting mold process typically takes around 40 days due to its critical role in ensuring precision and density for subsequent production. We anticipate some additional time for completion.

However, just the day before yesterday, we received exciting news from the mold factory: the molds have been successfully cast. The cast will be tested in the next few days to ensure its accuracy and durability. This brings us one step closer to mass production for VS01.

Progress on the other parts is ongoing, so rest assured. Stay tuned for further updates as we inch closer to delivering our product.

At last, we want to appreciate recent reminders from backers highlighting the importance of timely updates. VS01 is our team's first crowdfunding project, and we know some things still need improvement. Thank you for your timely feedback.

Apart from updates at significant milestones, we commit to providing regular updates between the 25th and 30th of each month until delivery to ensure transparency and keep backers well-informed about our progress.

If you have any questions, please comment below or email us at support@makagic.com.

Best regards,

MakaGiC Team