Dear Backers,

As mentioned in our previous update, we planned to conduct the PCB pilot production around January 30.

The actual pilot production took place on January 29, which was almost exactly in line with our original plan. Below, we’d like to share the results of this pilot run with you.

The goal of this pilot production was to build 15 sets of PCBAs, mainly to verify whether the current PCB design is suitable for mass production, and to prepare for the next step of establishing our assembly SOP for volume manufacturing.

On January 29, our team went to the factory to complete this pilot run. This facility supplies PCBAs for companies such as DJI and HP, and the overall production environment and process are highly professional. Our boards were manufactured in a cleanroom. This is what our PCB looks like at the very beginning.

This is what our PCB looks like at the very beginning. After cleaning, the board first goes through the solder paste printing process, where an automatic printer applies an even layer of solder paste through a stencil.

After cleaning, the board first goes through the solder paste printing process, where an automatic printer applies an even layer of solder paste through a stencil. Next, the SMT machine places electronic components such as ICs, resistors, and capacitors precisely onto the PCB

Next, the SMT machine places electronic components such as ICs, resistors, and capacitors precisely onto the PCB

The board is then sent through the reflow oven. Under controlled high temperatures, the solder paste melts and permanently bonds the components to the PCB. This step is extremely critical, as the temperature profile must be carefully controlled to ensure reliable soldering without damaging components. In most PCB manufacturing processes, the majority of defects originate at this stage. Because our PCB has components on both sides, the above steps need to be repeated once more. At this point, the board becomes what we call a PCBA.

Because our PCB has components on both sides, the above steps need to be repeated once more. At this point, the board becomes what we call a PCBA. After soldering, each PCBA goes through AOI (Automated Optical Inspection) to ensure that every component is correctly placed and properly soldered.

After soldering, each PCBA goes through AOI (Automated Optical Inspection) to ensure that every component is correctly placed and properly soldered.

Finally, the boards are cleaned and programmed with firmware. At this point, the PCBA is fully completed On January 29, we successfully completed the production of 15 sets of PCBAs, and the manufacturing process itself went smoothly.

On January 29, we successfully completed the production of 15 sets of PCBAs, and the manufacturing process itself went smoothly.

However, during functional testing conducted today, we discovered an issue. The laser signal received by this batch of boards is relatively weak. While the boards are usable, the performance does not yet match our previous test results. As mentioned in earlier updates, we had replaced the IMU and adjusted the circuit design.

After initial investigation, we believe this issue is caused by the placement of an inductor and a MOSFET, which are positioned suboptimally and affect signal performance. We therefore need approximately one additional week to revise the PCB design and revalidate its performance.

The good news is that the current IMU performance is very stable and meets our expectations. This means we no longer need to worry about potential risks caused by TDK chip price fluctuations. We will leave our validation results in the comments section of this update once the redesign is completed. Fingers crossed.

Overall, this PCB pilot production went quite well. There were some small issues, but we are actively addressing them. At this stage, the expected delay is around one week. We still aim to begin delivery by late February, and we will do our best to stay on track.

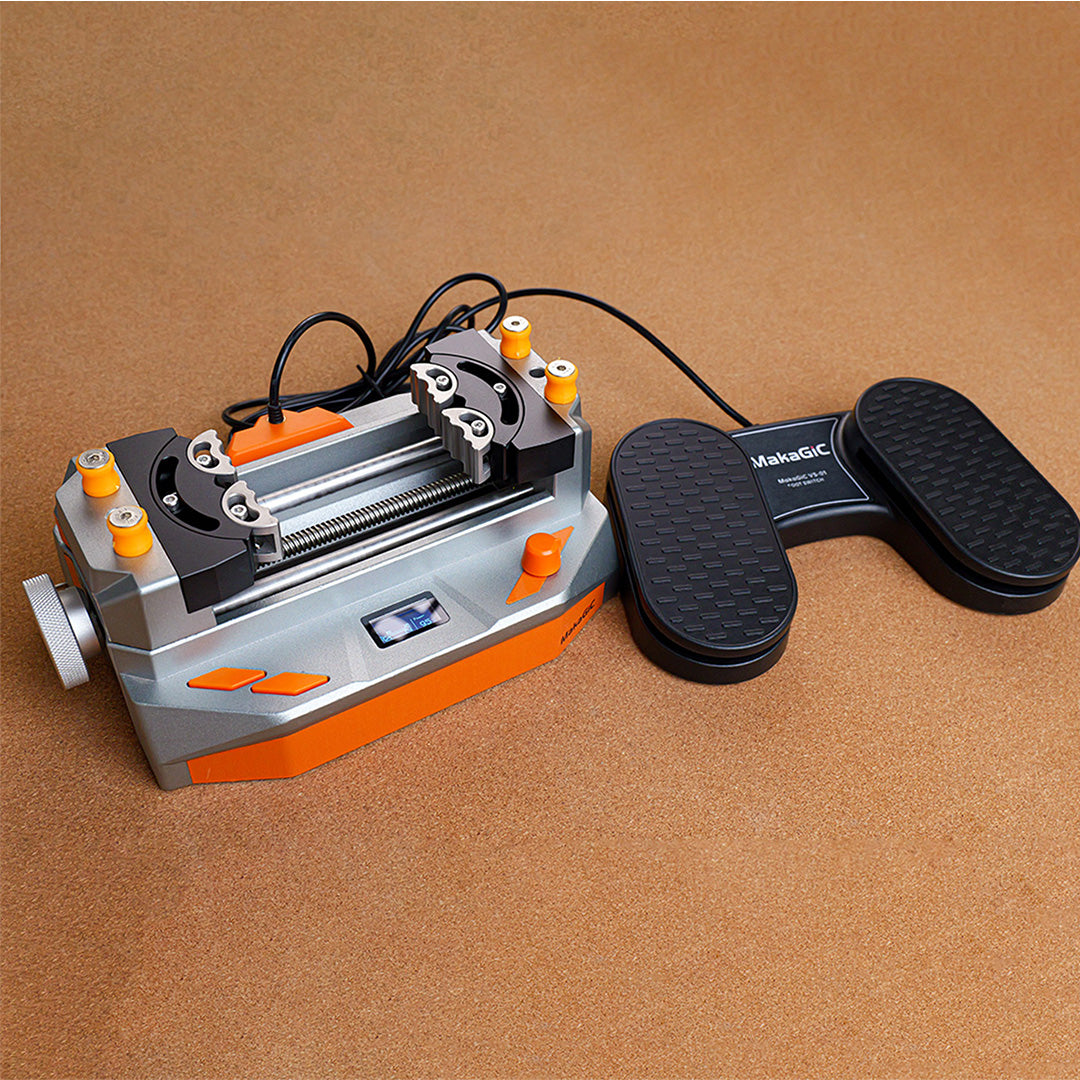

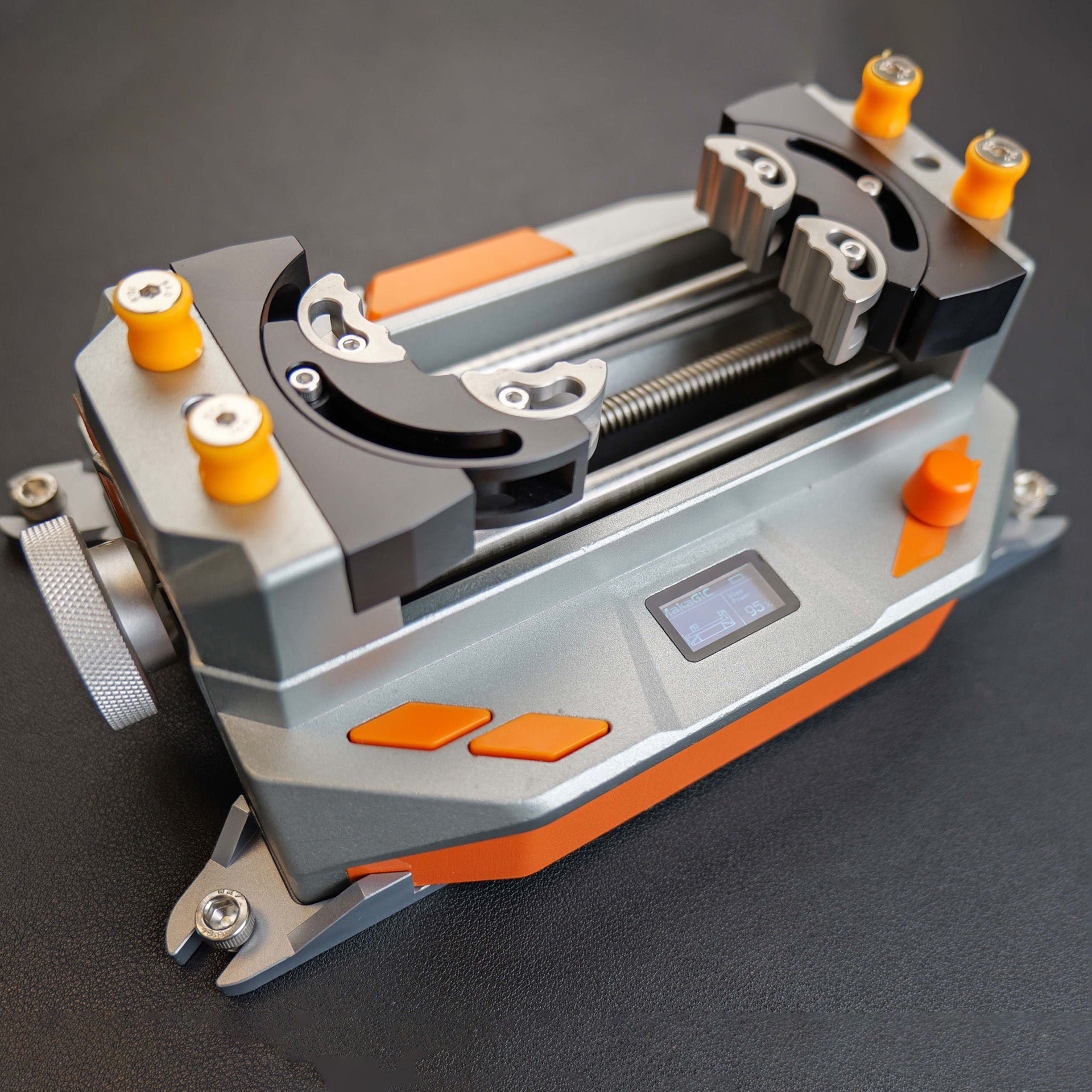

Next, we plan to start the final assembly pilot run on Wednesday, February 5. This stage involves assembling the PCBA, housing, and battery into complete products, followed by inspection and packaging. We expect to assemble 12 complete units during this step. This is the final and most critical stage of production. If everything goes smoothly, we will be able to move quickly into mass production after the holiday.

After this pilot run, China will soon enter the Chinese New Year holiday (February 14–23). During this period, most factories will be closed, and our team will also pause work. We sincerely apologize for any delays this may cause. Once the holiday ends, we will fully resume mass production and delivery.

Finally, thank you sincerely for your continued support and patience. We hope to earn your trust through transparency and steady progress.

Thank you to every backer—this product is only possible because of you.