It has been less than 10 days since our last update. With a longer holiday approaching, we wanted to share another progress update ahead of the break, so you have a clear picture of where we currently stand. First of all, thank you sincerely for your continued patience—we are still steadily pushing forward toward mass production.

Last week, as planned, we received the T1 mold parts (final appearance and structure) from our tooling supplier, along with our custom battery samples. At the same time, we completed and finalized the full assembly SOP (Standard Operating Procedure). Before the factory paused operations for the holiday, we secured one day of production time and officially started pilot production. The original plan was to build 15 units, but some optical modules failed incoming inspection and were returned to the supplier for correction, so the final pilot production quantity was adjusted to 10 units.

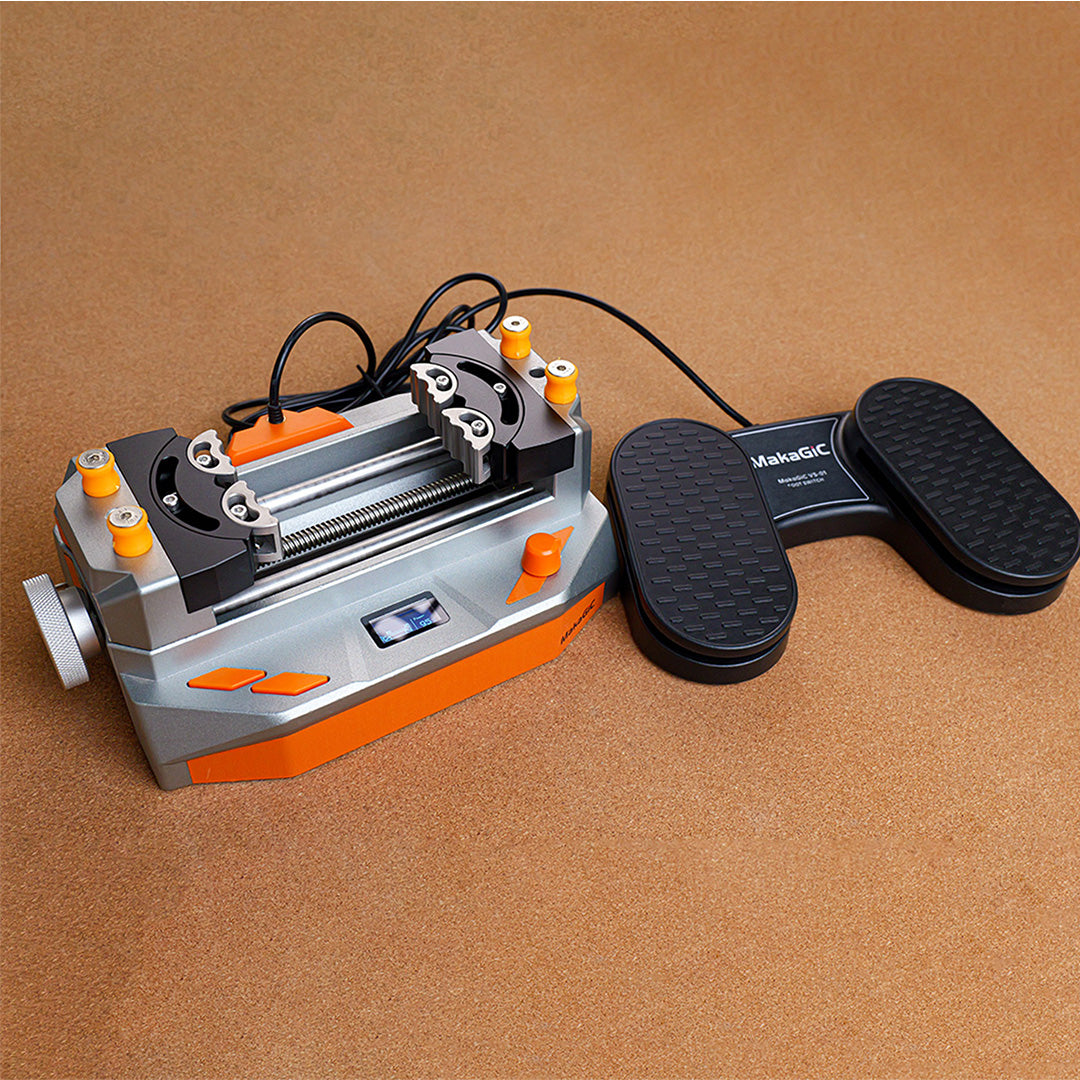

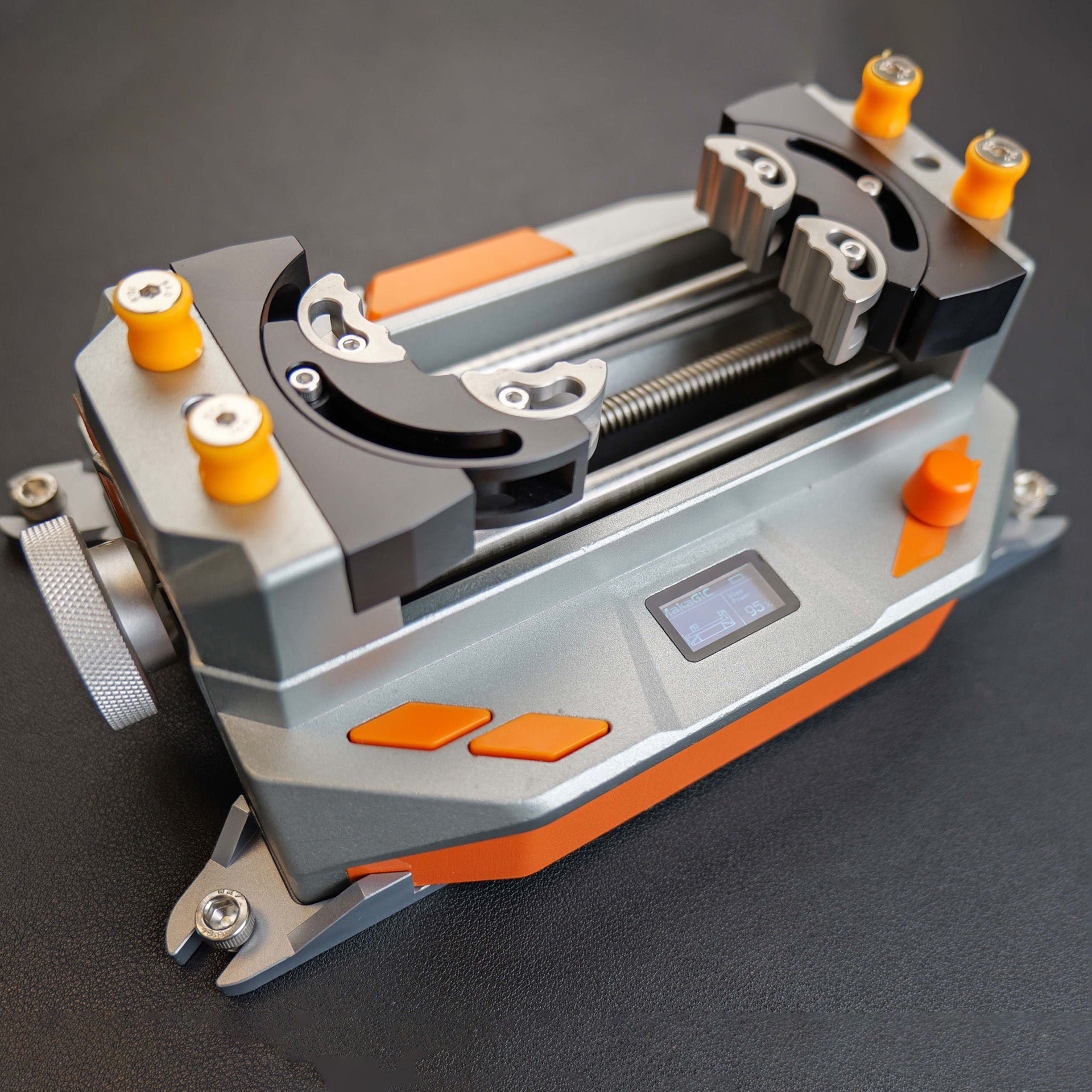

The photos below were taken by our engineers on-site during the pilot run. It is important to note that pilot production is very different from mass production. The primary goal at this stage is to verify the assembly sequence and ensure that the SOP is practical and executable. This process involves close collaboration between our engineering team and the factory’s NPI (New Product Introduction) team. That is why you are not seeing an assembly line here. In mass production, we will move to a line-based workflow and complete production in a clean-room environment.

During the pilot run, all incoming materials were strictly inspected according to the SOP by the NPI team. Unfortunately, the overall quality of this batch did not fully meet our expectations. The images shown represent only a small portion of the issues identified. While these issues do not affect functionality, they fall short of our quality standards—for example, the button color differs noticeably from our original design. These issues have already been reported to the supplier, and corrective actions are underway.

Thanks to a full day of close collaboration between our engineers and the factory NPI team, the pilot run was completed successfully. We assembled a total of 10 L7 units (only 6 are shown in the photos). At the same time, we further optimized the assembly SOP by analyzing the time required for each step and refining the assembly sequence. As a result, the assembly time for a single L7 has now been reduced to approximately 90 seconds. Overall, aside from incoming material quality issues, the pilot production itself went smoothly.

After assembly, we conducted systematic performance testing on all 10 units. At this stage, we encountered some issues that must be addressed seriously. Compared with our earlier engineering samples, this batch shows a noticeable performance gap. After switching to a new IMU, the stability of our spatial measurement feature—one of our core strengths—has declined (the previous IMU change was discussed in UPDATE 7).

We are currently observing two main phenomena. First, under the same environment and firmware version, different units exhibit noticeably different IMU trigger thresholds. Second, overall measurement stability has decreased. Previously, we would see roughly one inaccurate result out of 50 measurements; with this batch, inaccuracies can occur approximately once every five measurements. Our preliminary conclusion is that the newly selected IMU may have consistency issues under mass-production conditions, requiring further optimization at the algorithm and software level.

This is the first time we have identified this issue during mass-production preparation, and we believe it is our responsibility to communicate this transparently. Please rest assured—solving problems like this is exactly what engineers do best. We are actively investigating the root causes while refining our algorithms in parallel. While this is a challenge, we do not consider it an unsolvable one.

Once again, thank you for your continued support and patience. The above reflects our most up-to-date and honest progress. Our holiday period runs from February 12 to February 24. We are still aiming to complete tuning by the end of February and ship the first batch once product quality is fully ensured. While this remains a demanding goal, we will proceed carefully and continue to share updates openly. We wish you all a happy Lunar New Year and all the best!

We see our backers as partners in this process, and that means sharing both progress and challenges openly. With that in mind, we’ve put together a short FAQ below to answer the questions that may come up after this update.

And as always, if you have any questions, you’re welcome to reach out to us anytime

support@makagic.com.

FAQ

Q1: Is this a hardware defect? Will it affect the final product quality?

A:This is a consistency and tuning issue identified during mass-production preparation, not a hardware defect.

The issue relates to variation in the newly selected IMU under production conditions, rather than any functional failure or structural problem. All units operate normally, but to meet our standards for spatial measurement stability, further optimization at the algorithm and parameter level is required.

Identifying and resolving this at this stage is exactly how we ensure the final product delivered to backers meets our quality expectations.

Q2: Will this cause delays or require a hardware redesign?

A:At this point, we do not believe a hardware redesign is necessary.

We are addressing the issue through algorithm refinement and system-level tuning, which is a common and expected part of engineering development at this stage. Our goal remains to move forward according to plan while ensuring performance is fully under control.

If there are any material changes to the timeline, we will communicate them transparently.

Q3: Why was this issue not discovered earlier during prototyping?

A:This behavior only became apparent when we moved from small-scale engineering samples to a pilot production batch. Differences between individual units are much easier to observe when multiple devices are built and tested under the same conditions. Identifying issues at this stage is exactly why pilot production exists in the development process.

Q4: If the previous IMU was more stable, why not switch back to it?

A:This is one of the options we are actively evaluating. The IMU we previously selected, manufactured by TDK in Japan, has proven to be very stable and well-characterized in our system. However, shortly after our original design and validation work, the market situation changed suddenly and unexpectedly.

The price of this IMU increased sharply—from approximately $1.50 to around $20 per unit—and it entered a period of severe supply shortage. This shift was driven by a rapid surge in demand from the VR and drone industries, and it was not something we could reasonably anticipate during our earlier development and sourcing decisions. We expect market conditions may ease after the holiday period.

We are continuing to monitor both pricing and availability closely. If supply stabilizes and the price returns to a range we can reasonably accept (around $5 per unit), we are fully prepared to resume procurement and production using this IMU. It is a component we have already tuned to a very stable state, and the current situation reflects broader market volatility rather than a technical limitation.

Product development often involves navigating challenges beyond engineering alone, and our responsibility is to make the most balanced and reliable decision for our backers—taking into account performance stability, supply feasibility, and long-term sustainability.

Q5: Does this bring the product closer to mass production?

A:Yes. Pilot production is a key step between prototypes and mass production, and completing this run moves the project forward in a very concrete way. With the SOP validated and refined, we now have a much clearer path to scaling production once final tuning is complete.

Q6: How is pilot production different from mass production?

A :Pilot production is typically a close collaboration between engineering and the factory’s NPI team, focused on engineering validation rather than efficiency. Mass production, by contrast, uses standardized assembly lines with fixed workstations and takt times. Pilot production is about doing things right; mass production is about doing them right, repeatedly and reliably.